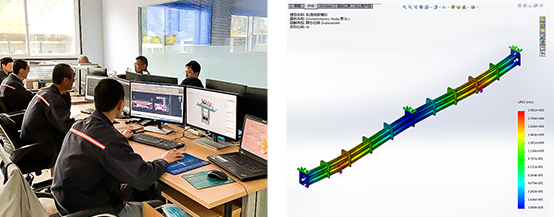

Design

Our excellent design team has rich design concept and experience of conveying equipment. Some technicians have been engaged in conveyor design for more than 30 years.

In the planning of related projects, the similar technology known to customers can be used to provide 2D and 3D computer-aided design, and high-intensity simulation is carried out for the simulation, so that the requirements of all parts of the pipeline are transparent, and the relevant design can be analyzed scientifically.